Drilling Site Safety

Safety from Planning through Clean-Up

Drilling is inherently hazardous, so we genuinely prioritize drilling site safety. Everyone at Premier Drilling Company is deeply invested in everyone’s safety and minimizing the hazards on every project. Our top priority is ensuring everyone on site leaves safely daily.

Safety Plan for Your Drilling Project

Your project safety plan begins at our pre-construction meeting and continues until the last equipment leaves your project site. Our Safety Director, Jeff Goff, prepares and distributes a safety plan specific to your project. Your safety plan supplements our extensive safety processes to address all potential safety risks related to your drilling project.

Risk Assessment on Every Shift

Every shift begins and ends with a written risk assessment. Our site reports include a checklist of items to inspect and situations to evaluate to ensure crews consider potential safety hazards throughout your project. Every report includes identifying hazards for each task, review of job site assessments, documentation of any deficiencies, and information about who corrected them.

Safety Throughout Each Shift

In addition to drilling site reports, your drilling team completes an assessment every time a critical task changes during a shift.

- Think through the task

- Recognize hazards

- Assess risks

- Control hazards

- Safety first and always

Completing a safety assessment requires thinking about the task and possible hazards and then planning to control those hazards. Safety assessments require team members to take a safety pause to ensure drilling safely.

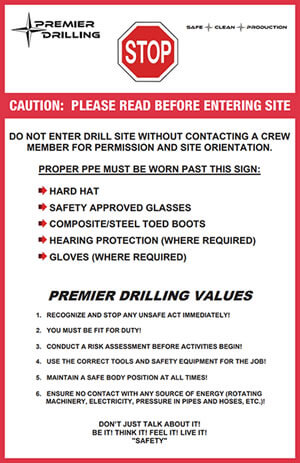

Premier Drilling Safety Values

Beyond risk assessments, as work proceeds, our crews follow our Golden Rules for Safety on every job:

- Recognize and stop any unsafe acts immediately.

- You must be fit for duty.

- Conduct a risk assessment before activities begin.

- Use the correct tools and safety equipment for the job.

- Maintain a safe body position at all times.

- Ensure no contact with any source of energy (rotating machinery, electricity, pressure in pipes and hoses, etc.).

Extensive Safety Measures

Our comprehensive safety program exceeds the requirements of our client’s safety programs. Our safety training and awareness starts with the moment our crew member sets out for their job site through their drive home.

Drilling Safety

Our crews don’t just talk about safety. They think it, feel it, live it. Every job, every day.

Territory: California and Nevada

Dedicated to Your Success

Contact us today at (480) 200-8300 to discuss your project with a drilling professional.

Safety Measures

Safety Certifications

MSHA Training

OSHA Training

HAZWOPER Training

Site-Specific Safety Plan

Safety Manager Visits

Safety Manager Oversight

Daily Safety Meetings

Weekly Safety Meetings

PPE

Safety Equipment

Rig Maintenance

Equipment Maint.

Task Training

Random Drug Testing

Zero Tolerance Policy

Driving Safety

Load Safety

Safety Measures

Safety Certifications

MSHA Training

OSHA Training

HAZWOPER Training

Site-Specific Safety Plan

Safety Manager Visits

Safety Manager Oversight

Daily Safety Meetings

Weekly Safety Meetings

PPE

Safety Equipment

Rig Maintenance

Equipment Maint.

Task Training

Random Drug Testing

Zero Tolerance Policy

Driving Safety

Load Safety